Simple Santa Manufacturing Shop (Part 1 — Overview)

Elements of the digital twin in manufacturing by example

Elon Musk once said that “manufacturing is underappreciated in general, and the difficulty of designing the machine that makes the machine is vastly harder than the machine itself" — using digital twins, digital representations of the resources and processes in a manufacturing environment, helps to tackle that complexity.

Without a doubt the hardest manufacturing and logistics operation on this planet is performed every year by Santa Claus and his elves creating christmas gifts for all children and distributing them in just one day.

There are reports on his north pole facility and hiring process so I thougt it would be a nice idea to describe the elements of the digital twin of manufacturing along his example.

I’ll try to keep it as simple as possible while maintaining a level of complexity which depicts common situations in realworld manufacturing environments.

Purpose : Happiness

Before going into the specifics how Santa’s manufacturing facility looks like we have to ask why he takes the burden to build and run such a complex operation — it’s actually to make children happy.

(Since Monsters Inc. we all know that Santa’s world runs by harvesting childrens laughter as the most potent power source on earth, but thats another story…)

So the goal of Santa’s venture is to make as much children happy as possible by delivering them their gifts, and every effort which doesn’t contribute to that goal is waste.

So how could santas manufacturing facility look like ?

Production Facility

Members of the recent Nonsens Fram Expedition are said to have spotted activities which indicate that the manufacturing facility is hidden on a large island in the direct vicinity of the north pole.

The production site on northpole has probably different stages on multiple levels, here is a schematic view how it could be organized, there is probably also a bakery in the basement where the cookies are created.

For now we concentrate on the workshop level, which has probably these different zones:

- raw materials arrive from suppliers at the inbound dock

- they are put in the storage zone until they are needed in production

- parts are picked and prepared for production or direct distribution in the supermarket

- the gifts are assembled in the assembly zone

- finally in the outbound dock zone everything is loaded into santas sleigh and flown of to the kids in the world ( as everybody knows santas sleigh has an unlimited loading capacity )

So what about the products ?

Products

To keep things simple we start with having only two kinds of products — toy buildings made of wood bricks and cookie baskets containing different sorts of cookies.

Brick buildings

Brick buildings get glued together in the assembly area using two types of bricks and glue, they are available in three different variants:

Cookie baskets

Cookie baskets get put together in the supermarket by picking and are available in three variants containing two different cookie types:

Material

We need five different parts to create the various products.

The material is delivered by different suppliers to the inbound dock and put in the storage area.

Production Program & Model Mix

There are estimates (here, here) that Santa Claus has to deliver gifts to about 526 million children each year. If we suppose that 1 out of 1000 children gets one of the products we concentrate on, we need to produce 526.000 units in one year.

Sources of the elves union indicate that there are 350 working days in the factory so we assume that we have to produce around 1500 units per day.

We use our experience from the last years to forecast the model mix to be as follows :

This results in total numbers per day : 375 Houses, 180 Towers, 120 Castles, 180 Cinnamon Star Boxes, 270 Ginger Bells Boxes and 375 Santa Mix Boxes.

So how do we capture this in our digital twin ?

Digital Twin Elements

Site Topology & Layout

To describe the structure of our production site we use the building topology ontology which defines bot:site, bot:building, bot:storey and bot:zone for our different production zones. The actual layout elements are described as bot:elements and assigned to their bot:zone. They will be described in detail when we get into the shopfloor layout.

Part type catalog (Material)

To describe our material we create a part type catalog containing all the parts which are build into our products:

Product catalog, Bill of Material (BOM)

In order to efficiently describe our products we use a rule based bill of material for each of our two base products. (If there is no variant rule the part is always built in)

Toy brick buildings:

Cookie boxes:

So now that we’ve described what we want to produce — how do we want to produce it ?

… see Part 2 — Assembly Planning

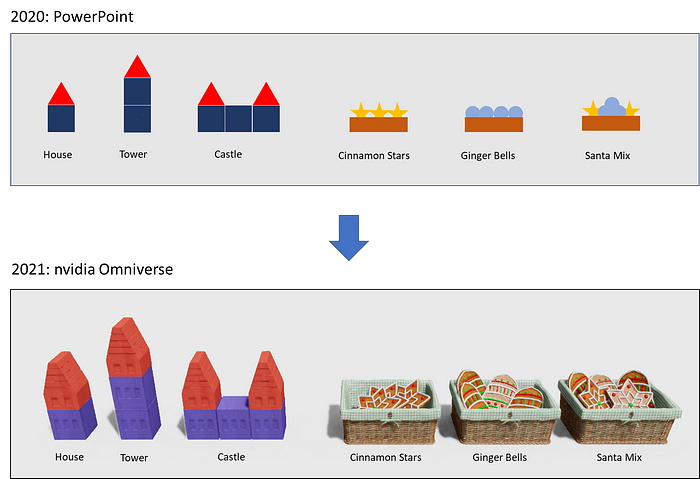

Update ’21 — nvidia Omniverse digital twin

If you have read this article last year you might have noticed that the drawings have fundamentaly changed —instead of creating them 2D in PowerPoint I’ve done them now in 3D in Blender, Unreal Engine & nvidia Omniverse using the RTX raytracing for rendering.

I’d like to thank the fine people of nvidia for creating Omniverse and providing support on composing the 3d scenes for this article, in the context of this article especially Teresa C. for giving good advice and directing me to the right people, Michael A K. for providing support and early access on the blender armature export version and Dane J. for pointing me to live pose capturing connectors.

I’d also like to thank Pixar for creating and opensourcing USD which is in the foundation of Omniverse and also epic for creating their Unreal Omniverse connectors which allow easy transfer of 3d scenery back and forth.

Update ’22

Sources familiar with the matter have leaked sensational new technical documentation of one of Santa’s core products: